Additional Information

What are Refractories ?

Materials which retain or improve on their normal strength under high temperature conditions are termed “Refractories”. Metals with high melting points, such as Tungsten & Molybdenum are known as “Refractory Metals” and not “Refractories”. Their uses in place of refractories is limited due to high cost.

Traditional refractories are manufactured from naturally occurring mineral composition, such as fire clays, siliminate, kyanite, bauxite, diaspore, dolomite, magnesite chrome‑ore etc.

Refractories are an integral part of industries, where heat in a manufacturing processes. Steels, Cement, Fertilizer, Chemical & Power plants, glass, aluminium, Petrochemicals, Engineering, Foundries, Boilers etc. are some of the industries where fire bricks are of common use.

Average Fire Bricks is 39% Al₂O₃ and 61% SiO₂ by weight. This kind of alumina‑silica mixture needs a fusion temperature of 1793 °C (3200 °F). High grade Fire Bricks are produced from clays that contain very little iron oxide and other fluxes.

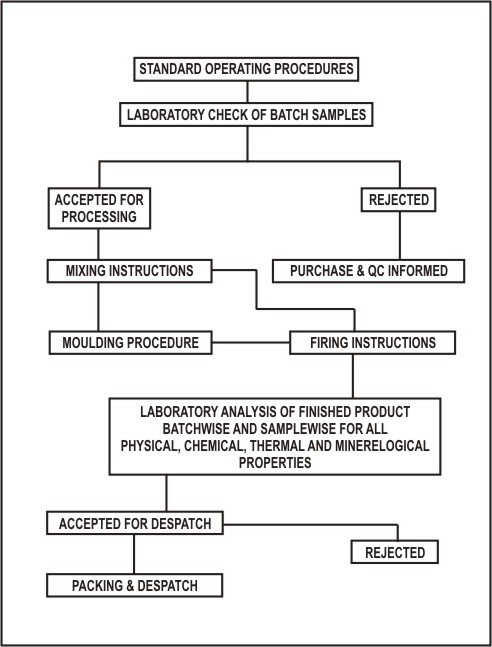

General Plant Procedures

Various Test Carried out

Tests which can be carried out in our laboratory in accordance to Indian standards tests

- Cold Crushing Strength

- Apparent Porosity

- Bulk Density

- Pyrometric Cone Equivalent

- Refractories Under Load

- Permanent Linear Change

- Spalling Resistance

- Thermal Conductivity

- Chemical Analysis

- Hot Modules of Rupture

- Sieve Analysis

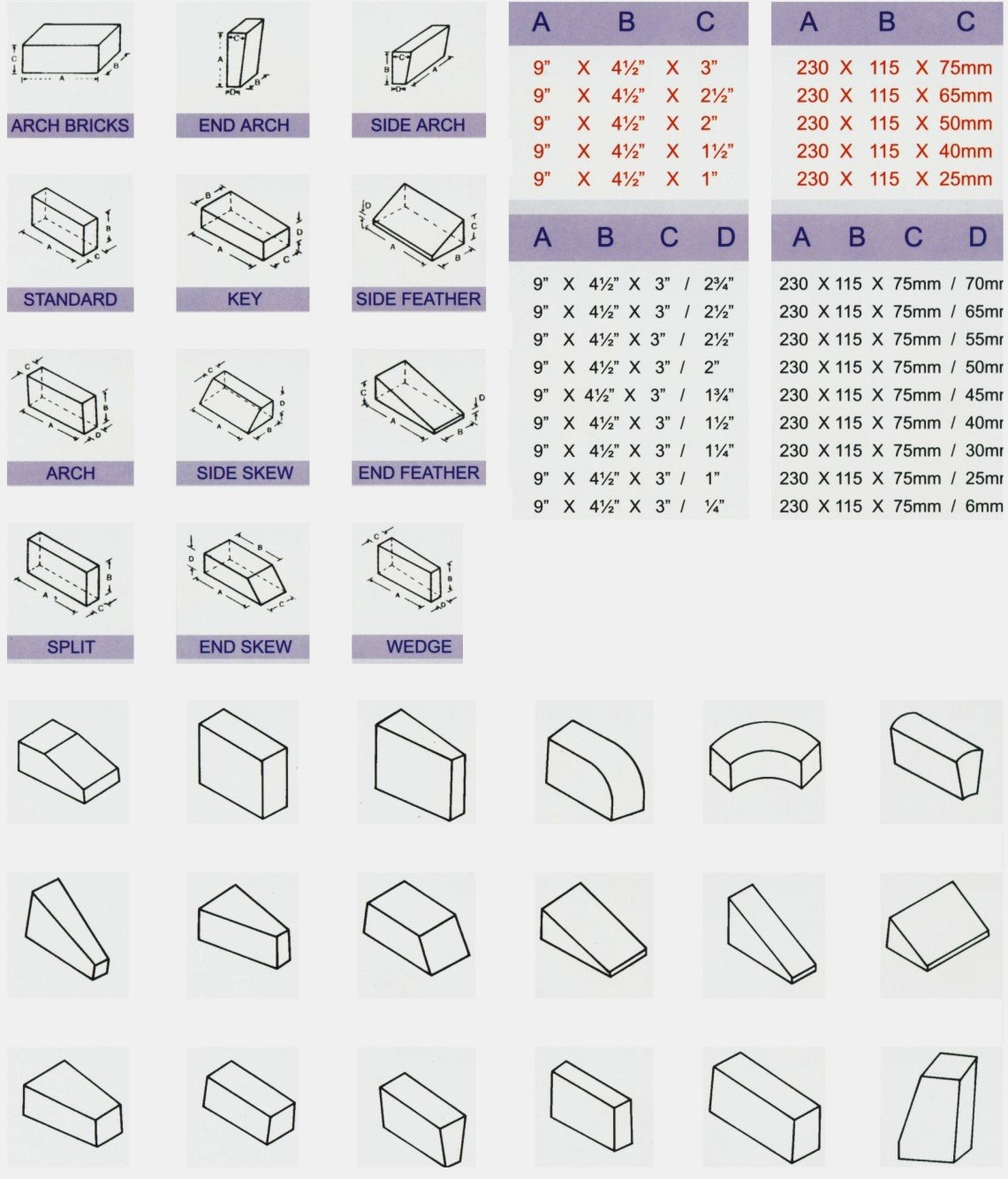

Standard Shapes of Bricks

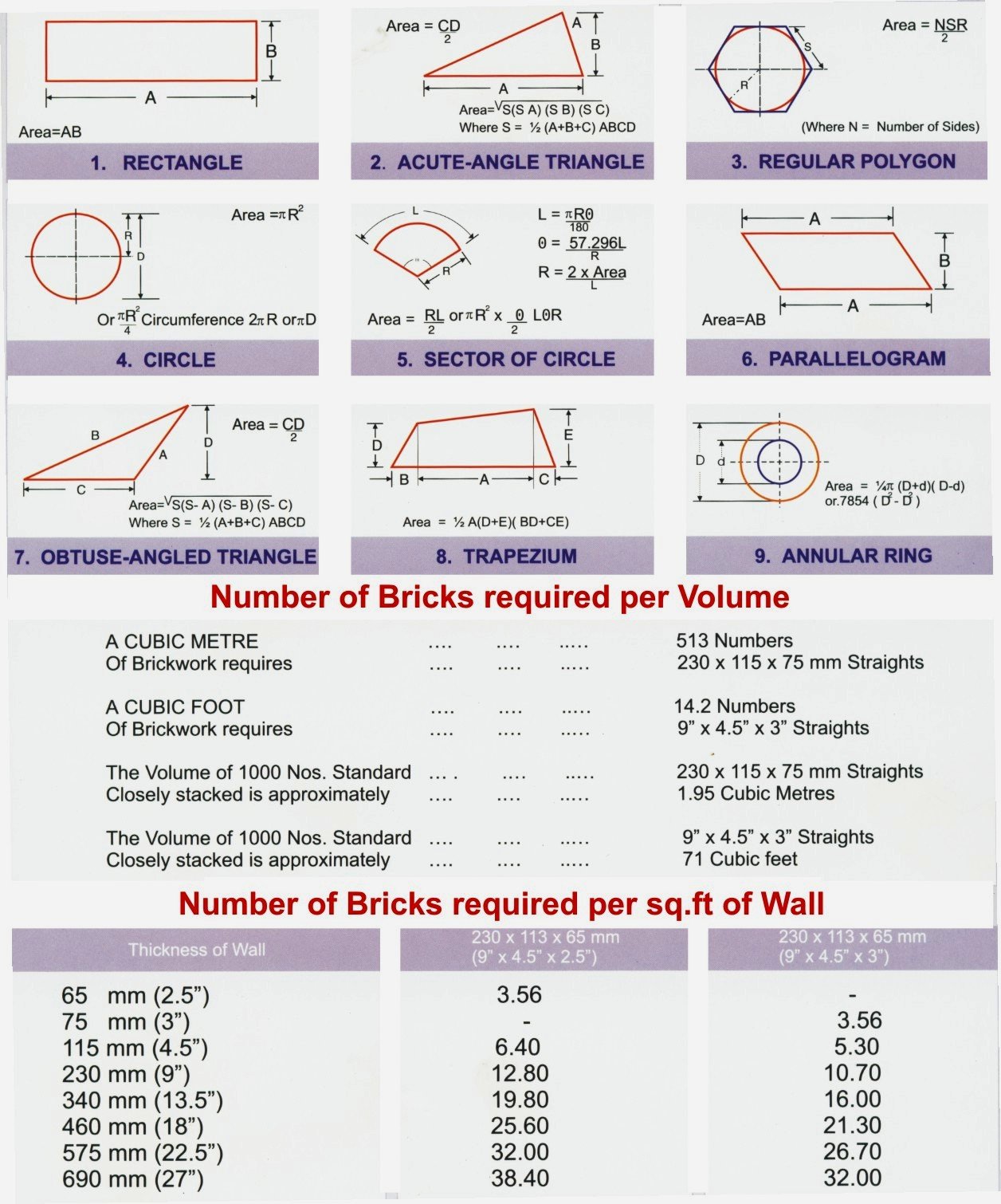

Number of Bricks Required (per unit / per sq.ft.)

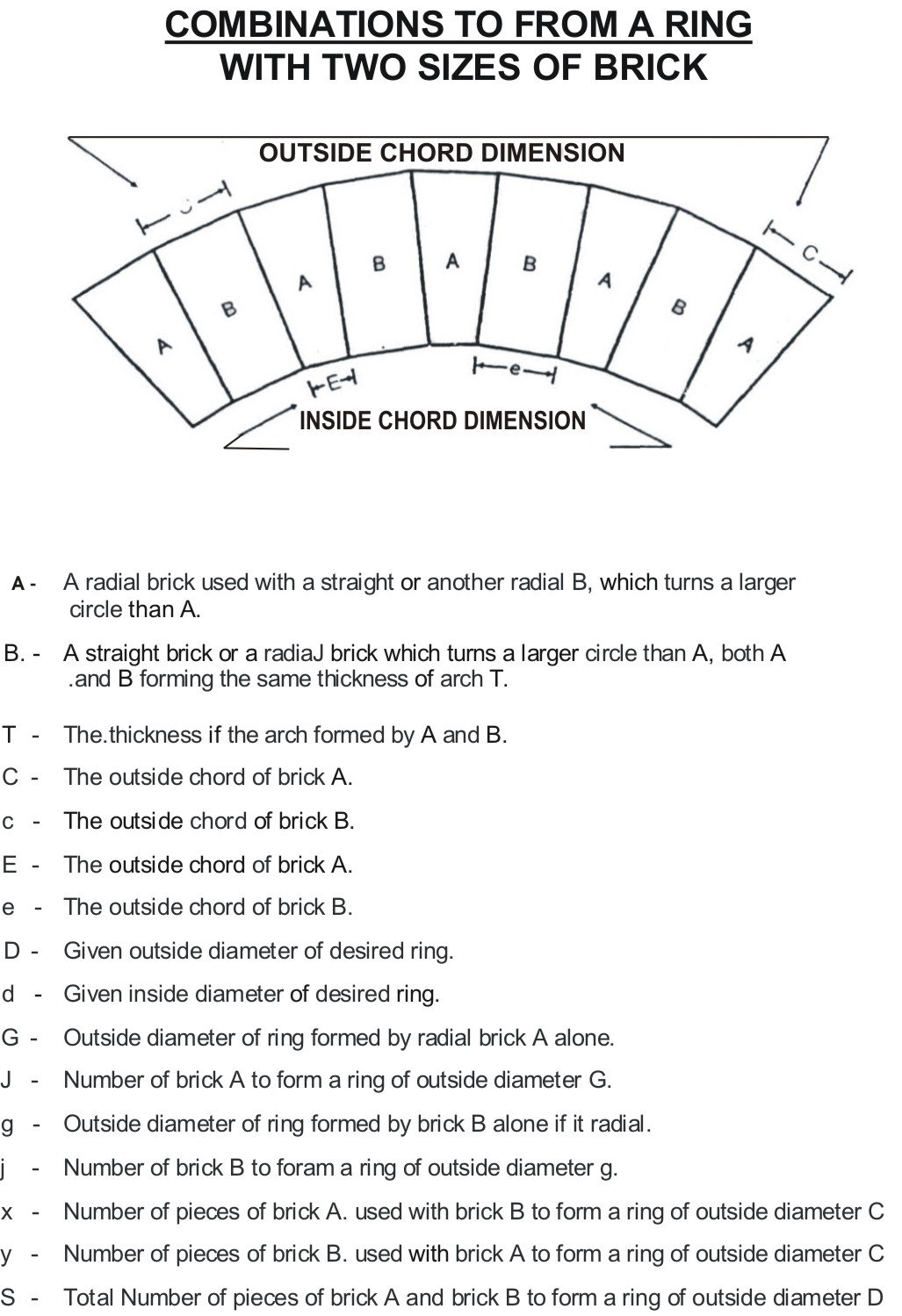

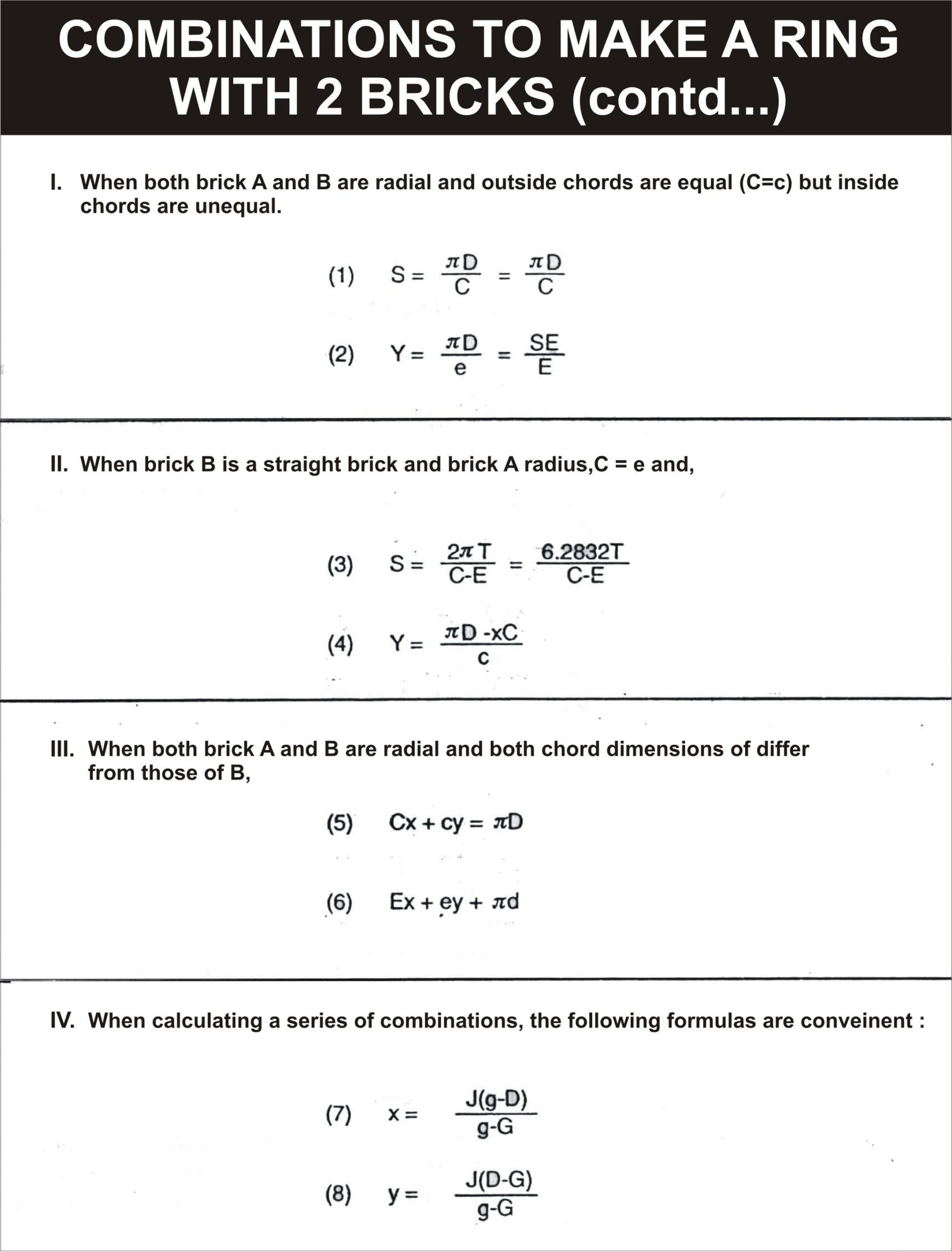

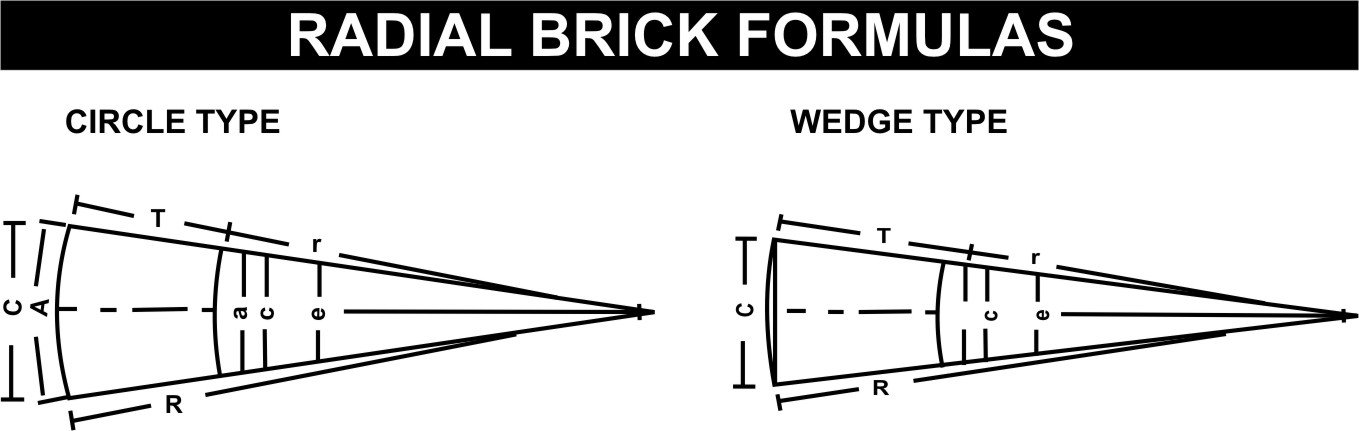

Combinations to form a Ring

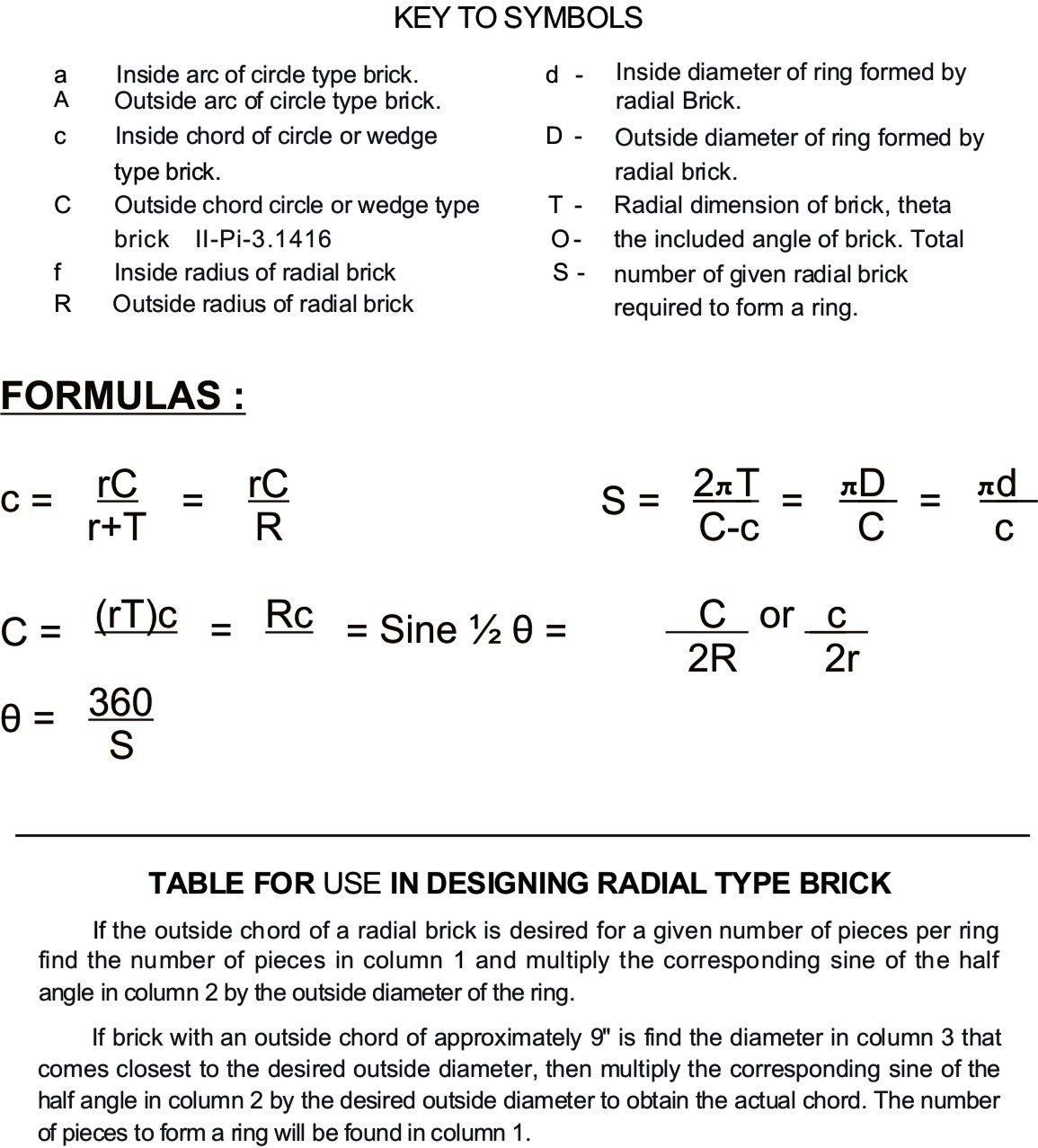

TABLE FOR USE IN DESIGNING RADIAL TYPE BRICKS |

|||||

|

No of brick to Circle |

Sine of Half Angle |

Dia. for 9 ” Chord in inches |

No of brick to Circle |

Sine of Half Angle |

Dia. for 9”Chord in inches (3) |

|

5 |

.58779 |

15.312 |

53 |

.05924 |

151.924 |

|

9 |

.34202 |

26.314 |

57 |

.05508 |

163.399 |

|

13 |

.23932 |

37.607 |

61 |

.05147 |

174.869 |

|

17 |

.18375 |

48.980 |

65 |

.04832 |

186.253 |

|

21 |

.14904 |

60.386 |

69 |

.04552 |

197.715 |

|

25 |

.12533 |

71.810 |

73 |

.04302 |

209.205 |

|

29 |

.10812 |

83.241 |

77 |

.04079 |

220.642 |

|

33 |

.09506 |

94.677 |

81 |

.03878 |

232.078 |

|

37 |

.08481 |

106.120 |

85 |

.03695 |

243.572 |

|

41 |

.07655 |

117.570 |

89 |

.03529 |

255.030 |

|

45 |

.06976 |

129.014 |

93 |

.03377 |

266.509 |

|

49 |

.06407 |

140.471 |

97 |

.03238 |

277.949 |

Terminology of importance in selecting Quality Fire Bricks

Terminology of Importance of Selecting Quality Fire Bricks

Fusion Point

The fusion point is specified as the temperature at which the particular specimen under a definite stress becomes sufficiently, fluid to flow at a specified rate. A common method of determining the fusion point’s by comparing. the bending characteristics of the sample with those of a series of standard pyrometric cones all run in the same furnace.

Load Test

ASTM Load Test-The load resistance of refractories are almost invariably measured with a comparison specimen, which is heated under a definite schedule and the amount of deformation determined at the end of the test.

Load test is generally carried out on smaller specimens i.e. cylinders approximately 1 inch in diameter and 1 inch high. This method is preferable

because the temperature can be made more uniform over the specimen.

Spalling

Spalling is usually defined as a fracture of the refractory brick or block resulting from a temperature gradient in brick, due to uneven heating or cooling that is sufficient to set up stresses of such magnitude as to cause failure.

Reheat shrinkage of Refractories

To determine the fitness of a particular brick for service, it is often tested tor shrinkage under temperature conditions equivalent to those which it would receive in use.

This is done by first determining the length or volume of the brick by measurement and then subjecting it to a prolonged heating at the desired temperature. After the brick has cooled, it is again measured and the length, volume and shrinkage determined.

Permeability

The flow of gases through refractory wall is important in many furnaces, especially where large pressure differences exist as in recirculating types. Also the permeability of such part as thermocouple tubes, muffles and recuperator is of interest in efficient design. Defects in manufacturing, viz, Laminations, voids and soft spots are shown up in the permeability test. Bricks made with more careful grog sizing, higher molding pressures and higher firing temperatures would have some what lower permeabilities.

Strength of Refractories

The cold strength of fired refractories is not generally of importance in itself ;however, it often serves as a guide to other characteristics such as vitrification, burning temperature, or purity of material.

Abrasion Resistance

Refractories used in the hearths of furnaces or other places where objects slid along them must have a good resistance to abrasion, in the first place, the refractory must have a strong well – bonded structure, and second it must not become plastic at the working temperature, in general a brick which shows good resistance to load will also resist abrasion.

Samples of refractory are rubbed together inside a furnace and the loss in weight is determined for a certain time of test. Abrasion resistance decreases with the temperature. A fine grained structure and a high burning temperature increases the abrasion resistance.